Results 1 to 8 of 8

-

13-11-2010, 09:54 #1User

- Join Date

- Jun 2010

- Posts

- 357

A day in the life of Burger knives. Custom makers.

A day in the life of Burger knives. Custom makers.

A day in the life of Burger Knives (the making of the EXK1).

There has been a lot of talk lately of the EXK on bladeforums. I received my first Burger EXK in April 2008, here is that review http://www.spyderco.com/forums/showthread.php?t=33014. I am very pleased with this knife and the service given to me. Trevor Burger, the maker of the EXK is a great person and has gone above and beyond to help me with the purchase of this knife and all my questions at our recent knife makers guild show. I easily talked to him for almost half an hour and it was great to know how passionate he is about making knives.

This post is more to show how this great knife has been made and what effort is put into making a knife of this calibre. I truly hold this knife in high regards as an EDC and a pocket knife I can use around the camp and hiking trips.

First some history on the knife and its design:

The brief history with the EXK model is that is was originally( and still is) a collaboration knife between Burger Knives and Mike Skellern. When the collaboration started, going back+/-20 years the work load was shared between the two knife shops of Burger and Skellern, this was the case for many years. The collaboration knife had the EXKELIBUR logo( a play on Burger and Skellern names)

Over the years we decided to change from the EXKELIBUR logo and make use of both our individual logos as this was more suited to the custom knife market we operate within.

As situations and personal have changed over the years, the current set up with the EXK is that if your knife has a SKELLERN logo it was made by Mike and if your knife has the BURGER logo it was made by Burger Knives. We still continue to enjoy our collaboration and it gives us great pride in producing this popular folder.

Burger knives are located +- 2 hours drive South of Durban, in Munster on a Banana Plantation KwaZulu-Natal in South Africa. Their workshop is a former house that was build on their plantation (Co-ordinates in Google earth are: 30°59'18.67"S 30°15'3.47"E I think? It is somewhere in that area). When reaching the Burger workshop you are greeted by the following sight:

Greeted by Mr. Fred Burger the founder of Burger Canes and Burger Knives. This is their outside shop where you can also purchase the knives in showcased in their display area.

Home of “EXKELIBUR” KNIVES (I want one of these in my house, but my girlfriend thinks I am nuts!)

Scribing the various components for the knife. This EXK has full carbon-fibre scales

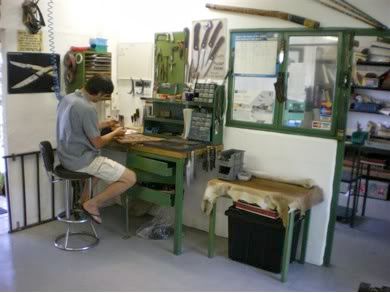

Trevor Burger at work on the knife.

Maker at work

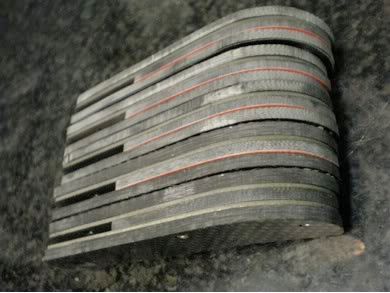

Various EXK components. (The red piece in the picture can be seen in one of my later photos where I show the backspacer).

-

13-11-2010, 09:54 #2User

- Join Date

- Jun 2010

- Posts

- 357

Re: A day in the life of Burger knives. Custom makers.

Re: A day in the life of Burger knives. Custom makers.

Drilling

Initial assembly before periphery profile of the knife.

Profiling periphery.

Some more carbon goodness!

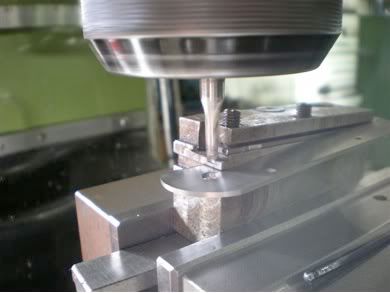

Milling spring lock face

Final lock sitting, grinding blade lock face

-

13-11-2010, 09:55 #3User

- Join Date

- Jun 2010

- Posts

- 357

Re: A day in the life of Burger knives. Custom makers.

Re: A day in the life of Burger knives. Custom makers.

Checking blade attitude and lock

The picture is the Rockwell hardness machine that Trevor uses to test the blades with.

Final assembly and inspection is done by Trevor Burger and he signs a certificate of authenticity with the knife.

So that is it for the making of the knife. The following is all the things that I use a knife for in life. Since I am a student and low on cash I make due with what I have. Doing Environmental Management we have to take samples, fix sprinkling systems in certain context etc. The EXK is always with me and I have found it to do all the tasks I ask of it.

First a look at the G-10 on the handle.

Nice and grippy!

The red line in between the backspacer and the liner is the red piece in the photo of the various EXK components

First task was to make some lunch. Tomato, chicken and mayo sandwich. This was obviously an easy task for a knife with such great slicing ability.

-

13-11-2010, 09:56 #4User

- Join Date

- Jun 2010

- Posts

- 357

Re: A day in the life of Burger knives. Custom makers.

Re: A day in the life of Burger knives. Custom makers.

Next up was time to do some fire practicing. The blade gives off a nice spark for me and I like that the spine of the blade near the pivot is square and forms a nice 90* edge to use as a striker on the flint and near the tip the spine starts to be rounded like on a Sebenza.

Next up was to sharpen my pencils:

After all of this I finally decided to touch up the edge a bit. I use my Lansky crock stick (TurnBox kit) to maintain my edges. About twenty strokes on the fine rods and it could cleanly cut toilet paper and with some leather stropping got a nice keen edge

---------- Post added at 09:56 ---------- Previous post was at 09:56 ----------

The following photos are to show the blade length in inches and millimetres. These photos are a bit off centre as I could not find my ruler.

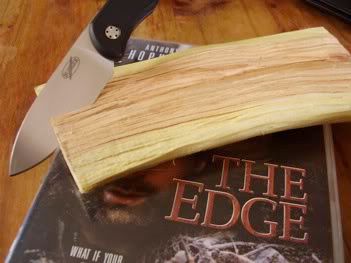

And after a long day what better way to relax with a great movie?

Now for your viewing pleasure some videos of the EXK and photos.

-

13-11-2010, 09:58 #5User

- Join Date

- Jun 2010

- Posts

- 357

Re: A day in the life of Burger knives. Custom makers.

Re: A day in the life of Burger knives. Custom makers.

Different Context

---------- Post added at 09:58 ---------- Previous post was at 09:56 ----------

Conclusion.

This is a great knife for EDC and camping purposes. I am extremely happy with the fit and finish of the knife and it has proven itself to be a fantastic companion. I recommend this knife to anyone that want a good quality working knife that appreciate the fact that it is made by hand and it is something you can be proud to own.

I have the new EXK with a thicker 2mm liner and it performs just as well as the older model discussed here.

Trevor offers an array of different steels you can chose from. N690 Bohler, S30V and D2 with a choice in Carbon Fiber handles, Digital Camouflage and normal black G10. The new website is

www.burgerknives.co.za

Hope you enjoy!

-

13-11-2010, 16:16 #6User

- Join Date

- Apr 2010

- Age

- 53

- Posts

- 25

Re: A day in the life of Burger knives. Custom makers.

Re: A day in the life of Burger knives. Custom makers.

Good looking knifes Mr Burger.

-

14-11-2010, 14:09 #7User

- Join Date

- Sep 2008

- Age

- 37

- Posts

- 4,042

Re: A day in the life of Burger knives. Custom makers.

Re: A day in the life of Burger knives. Custom makers.

Looks awesome!!! how much do they go for here in SA? (had a look on the site, and all pricing is in USD$)

-

15-11-2010, 11:27 #8User

- Join Date

- Jun 2010

- Posts

- 357

Re: A day in the life of Burger knives. Custom makers.

Re: A day in the life of Burger knives. Custom makers.

My new one as shown in this post with the full kit, the price if I remember correctly, was R1700 about. Without kit it is cheaper. Give him a call.

Tell: +27 (0)39 319 2316 end_of_the_skype_highlighting

Cell:+27 (0)72 200 4448 begin_of_the_skype_highlighting

That would be the best option.

Here are some pictures when I received the CF model EXK.

Here are a few photos next to the old EXK model:

Similar Threads

-

First custom/handmade: Gecko Knives

By GerhardG in forum Custom KnivesReplies: 6Last Post: 21-04-2015, 07:27 -

Ever saved a life your own life or used your FA in a defensive situation?

By bronxlive in forum General Firearm DiscussionReplies: 16Last Post: 21-06-2013, 22:01 -

Gareth Bull Custom Folder, ispired by Hinderer, CRK, Strider and Burger knives

By marthinus in forum Custom KnivesReplies: 10Last Post: 18-08-2011, 01:19 -

Arm - Ko Knives - Custom Knives by forum member ' harm '

By harm in forum Miscellaneous Goods for Sale / WantedReplies: 10Last Post: 07-10-2008, 13:58

Reply With Quote

Reply With Quote

Bookmarks