Results 1 to 10 of 11

Hybrid View

-

02-07-2016, 20:45 #1User

- Join Date

- Jul 2010

- Location

- Witbank

- Age

- 59

- Posts

- 4,126

.577 Snider load development -the first phase.

.577 Snider load development -the first phase.

Good day to you members.

My good friend Herman Nel own a .577 Snider. He commenced on a journey to develop a load for the .577 Snider. Herman enlisted the assistance of Hansie Minnaar ( Steward Bullets)who took over Stan Steward`s brass/ bullet fabrication.

Hansie Minnaar made brass and cast bullets for the .577 Snider owned by Herman Nel. Hansie and Herman did a chamber cast on the .577 Snider to determine the bore diameter of the rifle.

Recently , while visiting Herman Nel for another building/brass casting project we set out to see how good grouping can be shot with the .577 Snider.

Herman commenced by paper patching the 420 gn hollow core bullets:

The bullet swage block and paper for paper patch...

Paper patching the bullet:

Paper patched bullets:

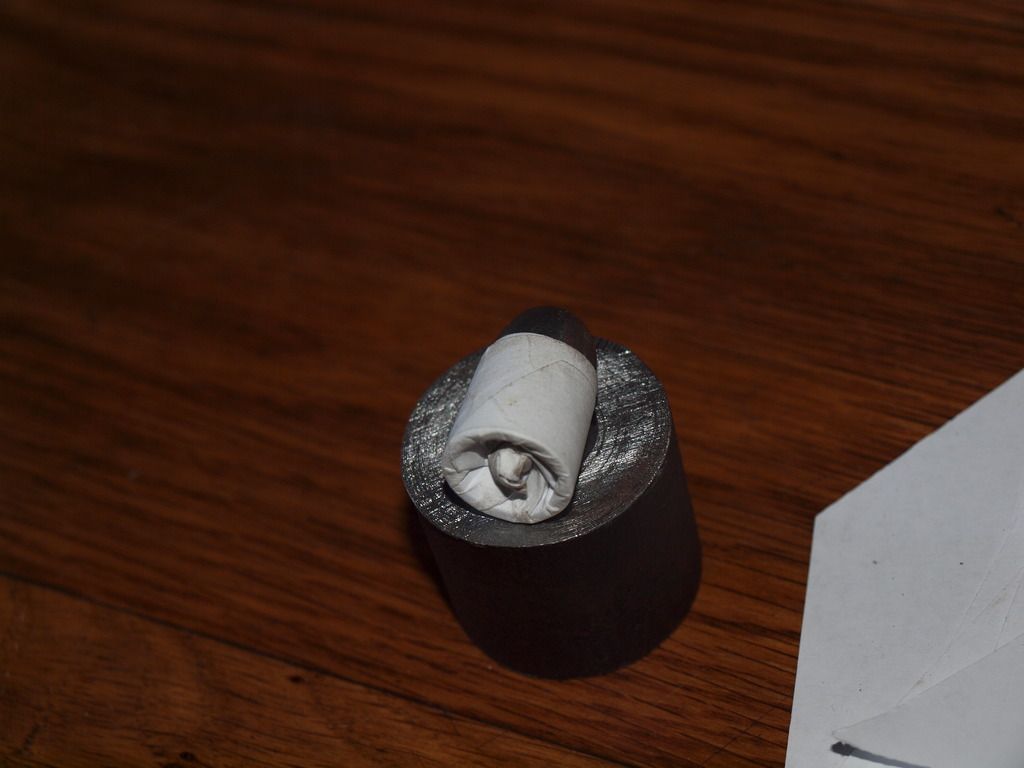

The paper patched bullets are dunked into a mixture of beeswax/olive oil, seated and then the whole bullet /paper patched surface is dunked in the hot liquid again:

Excess wax is removed by thumb nail to ensure a tight fit in the chamber:

Fit the chamber :

The shooting range on the farm, back stop is extremely dense potters clay:

Herman Nel shooting at the target:

Ruan and me did some shooting as well , to see if a good grouping can be achieved ...

We did manage to get acceptable groupings. One of the problems was that the bullet tend to tumble with the first lot of loads that was develop.....these following pictures shows the tumbling had stop with the new loads and paper patch bullets. This photo indicate a straight line penetration, extremely deep penetration since the potter`s clay is extremely dense and hard .

What is evident as well is that the bullets Herman shot is extremely hard lead as well since deforming did not occurred when deep penetration into the dense clay took place:

This is the distance the bullet penetrated..at least eight inches into this dense potter`s clay wall that is the back stop..

The bullet lodged in the clay...

The bullet`s path of penetration:

Distance of penetration/wound channel:

.577 Snider bullets retrieved:

Conclusion:

We all got good groupings at seventy meters, but everyone who shot this rifle concur that the sights is not up to standard and therefore Herman Nel will build a ghost ring aperture sight for this rifle and a larger front bead to enable him to see the sights better and increase accuracy.

Phase two will be about the designing of a ghost ring and front bead to increase accuracy....

-

02-07-2016, 21:26 #2User

- Join Date

- Dec 2012

- Location

- Kansas

- Age

- 68

- Posts

- 63

Re: .577 Snider load development -the first phase.

Re: .577 Snider load development -the first phase.

great pics...what load?

-

02-07-2016, 21:58 #3User

- Join Date

- Jul 2010

- Location

- Witbank

- Age

- 59

- Posts

- 4,126

Re: .577 Snider load development -the first phase.

Re: .577 Snider load development -the first phase.

quicklysharps4570

I stand to be corrected , it was 70 gn of FFFg it is the only black powder ( priming powder) he has currently, Herman will purchase FFg and Fg for a future load development .We are still working on a better load development...so the FFg /Fg will surely assist in the load development ...

...

Maybe I should give some info regarding the .577 Snider rifle:

The .577 Snider cartridge was a British black powder metallic cartridge, which fired a 14.7-millimetre (0.577 in), 31-gram (480 gr) lead projectile, primarily used in the Snider–Enfield rifle.

Early .577 Snider cartridges were made from paper, with a metallic base and primer, but later commercial cartridges were made from drawn brass, much like modern small arms ammunition. The .577 Snider cartridge was eventually replaced in service by the .577/450 Martini–Henry cartridge in the 1870s. The .577 Snider cartridge is considered by most commentators to be obsolete, with large scale commercial production having ceased in the 1930s. However, as of 2012, cases, bullets and cartridges as well as others of the .577 family are available from Tenbury Guns Limited in the United Kingdom. New brass can be formed from a 24 gauge hull and reloading dies are available from Lee. As of 2015, Kynamco in the United Kingdom and Bertrum in Australia are also producing ready-made brass.Last edited by Gert Odendaal; 02-07-2016 at 22:19.

-

01-10-2018, 13:47 #4User

- Join Date

- Apr 2015

- Age

- 65

- Posts

- 1

-

01-10-2018, 15:40 #5User

- Join Date

- May 2011

- Location

- GP, but in my mind, hunting for Ivory in the 1930's

- Age

- 43

- Posts

- 6,261

-

01-10-2018, 18:15 #6Banned

- Join Date

- Aug 2012

- Location

- Stella

- Age

- 46

- Posts

- 10,870

Boffie, half the fun of shooting these old ladies is doing research and developing loads. You can probably find cartridges for sale, but most probably at a steep price. The other benefit of reloading is that you would be able to develop a more accurate load for your rifle.

-

02-07-2016, 23:59 #7Banned

- Join Date

- Jun 2015

- Location

- Florida USA

- Age

- 81

- Posts

- 231

Re: .577 Snider load development -the first phase.

Re: .577 Snider load development -the first phase.

I noticed that the paper-patched cartridges didn't seem to be crimped tightly to the bullet. (At least it doesn't look like it in the photos.) Is that the case?

If it is, does the seating die have case crimping ability? If crimped tightly, it would allow pressures to rise and perhaps give a constant pressure which should contribute to better accuracy and very little variation in velocities.

As I understand paper-patching, it is to give a better fit of the bullet to the lands and increase accuracy. Could the same thing be accomplished by casting a softer alloy by adding stick-on wheel weights to the lead mix and swaging the final product to produce the same thing? The softer alloy would also allow for more expansion in a hunting situation. It would also allow the hollow base to expand somewhat like the "apron" of a minie ball and seal the bore better.

Sorry for the run-on but new things kept popping into my head as I was typing.

-

03-07-2016, 06:29 #8

Re: .577 Snider load development -the first phase.

Re: .577 Snider load development -the first phase.

Great write-up!

Quemadmodum gladius neminem occidit: occidentis telum est.

Seneca (4 BC - 65 AD)

-

03-07-2016, 08:18 #9User

- Join Date

- Jul 2010

- Location

- Witbank

- Age

- 59

- Posts

- 4,126

Re: .577 Snider load development -the first phase.

Re: .577 Snider load development -the first phase.

Patocazador

You are quite correct. The bullet lead composition is to hard, I am sure it can be use on dangerous game ... Herman is going to use a softer lead composition , for a tighter grip of the rifling, this rifling is a three groove Withworth rifling.

Herman is going to use a softer lead composition , for a tighter grip of the rifling, this rifling is a three groove Withworth rifling.

The paper patch piece shot out of the rifle already show a print of the grooves on the paper.

Herman is currently busy making a die set for the .577 Snider with Hansie Minnaar assisting him.

-

03-07-2016, 10:39 #10Banned

- Join Date

- Aug 2010

- Location

- Port Elizabeth

- Age

- 56

- Posts

- 11,588

Re: .577 Snider load development -the first phase.

Re: .577 Snider load development -the first phase.

Gert been meaning to ask when I met the right person, I see hear about paper and cloth wrapped bullets - two questions.

First - why not just have correct sized bullets as apposed to correcting size with paper ?.

Secons _ i always wonder would this paper thin lead sheeting you get not be a better wrap than paper. Surely it would seal , bite , engrave better than paper and its more engrave able malleable.

Reply With Quote

Reply With Quote

Bookmarks